Quality Rotomold Tooling Processes – From Start to Finish

At Viking Mold, we’re committed to excellence, so we pay careful attention to our tooling at each and every part of the production process. Thanks to our commitment to our craft, we’ve earned a reputation for top performance and quality in the rotational molding tooling industry.

State-of-the-Art Design

When designing a mold, we work closely with both our clients and our team to enhance your designs, converting your concept into the exact mold you had in mind. We’re also proud to use the premier industry software – SolidWorks CAD/CAM software – which will easily convert almost every type of file.

Competitive Pricing

We are committed to giving you competitive industry pricing on all of your molds and tooling. We provide the quality and service you expect for the best price possible.

Quality Customer Service

At Viking Mold, we take pride in our working relationship with our customers. This starts with customer service. Our experienced team will work alongside you to create the highest quality mold and to ensure that the mold arrives to you ready for production. You won’t find better customer service anywhere.

Production

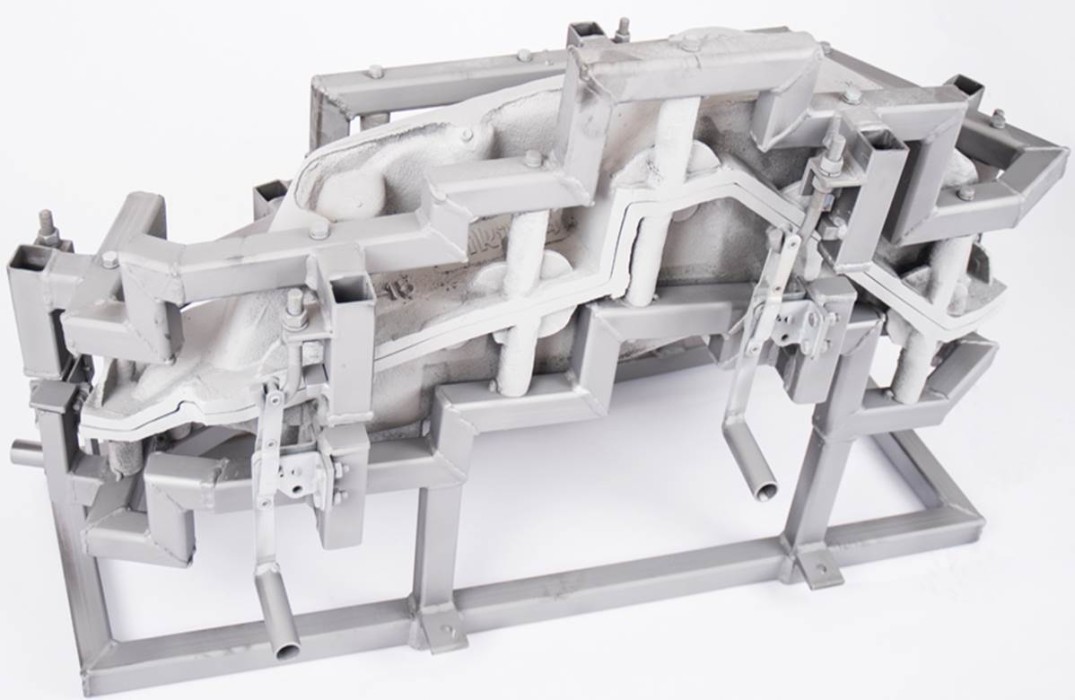

The Viking Mold facilities are state-of-the-art, set up with the best and newest features to make sure that your rotomold tooling production is seamless. We’re outfitted with all the latest equipment to both create standard molds as well as complex and large molds.

Our team of craftsmen are capable and experienced. Many of them have more than 15 years of experience in the rotational molding tooling industry. You won’t find porosity issues or metal imperfections with Viking Mold – our aluminum molds and castings are the best quality in the business. All of our tooling and molds are made in the USA with pride.

Quality Assurance at Every Step

Before we ship, we inspect each mold to make sure it has been manufactured to your exact specifications. We’ll send you photos and inspection reports with every shipment so that you can be sure it’s right. We also use the world’s best-selling measurement arm – the FaroArm – to ensure product quality and the correct layout of insert locations. Your product is delivered on time – every time.